Can't believe it has been 6 months since I posted any progress. The car is all back together and and has been my daily driver since early March.

Since the Audi has been functioning as a car I have been doing mostly cosmetic stuff and non-EV maintenance tasks. After I got the car moving there was a shuttering when I would accelerator, it was the same as it did with the ICE engine. When the ICE engine was installed, I assumed it was a cylinder missing because it would smooth out when I let off the gas. Same feel with the electric motor was installed? Well now I know what a CV joint going bad feels like. Without the ICE motor it only took a couple hours to replace the 1/2 shaft with a new performance unit from Raxels.

After driving around with aluminum battery boxes for a few months, it was time to upholster them so they don't standout as much. I used some 3/8" fiber board covered with carpet backing foam and upholstery fabric over it. The panels are attached with some velcro so they can be easily removed for any battery maintenance. The biggest benefit of having these installed is the reduction of the road noise that can be heard. Also it looks more like completed car rather than a project.

One of the most annoying parts if driving the Audi has been the oil warning built into the gauge cluster. Not only would this oil can flash up on the dash, there was a loud annoying tone to go along with it.

The Audi has an oil pressure switch that closes contacts when there is 10 psi of oil pressure, easy enough to just ground the wire so it always thinks it has oil pressure. The problem is when RPM is 0 it expects the pressure switch to be open, if it is closed it gives the same warning every time the motor stops turning. The beeping at every stop sign got old very fast. The first attempt fix this was using a few components and a transistor to pull the oil pressure low whenever a tach pulse was received.

This worked OK after some tweaking of the pots to get the timing dialed in. For most driving this worked fine but I could never workout the settings for when the car would just creep slowly. There was a hysteresis required that this simple circuit just could not provide. Probably could have done something with discrete logic but I have been looking for an excuse to do an Aduino project and do a little programming. I have not done programming since I took FORTRAN in collage so a small project is what I needed.

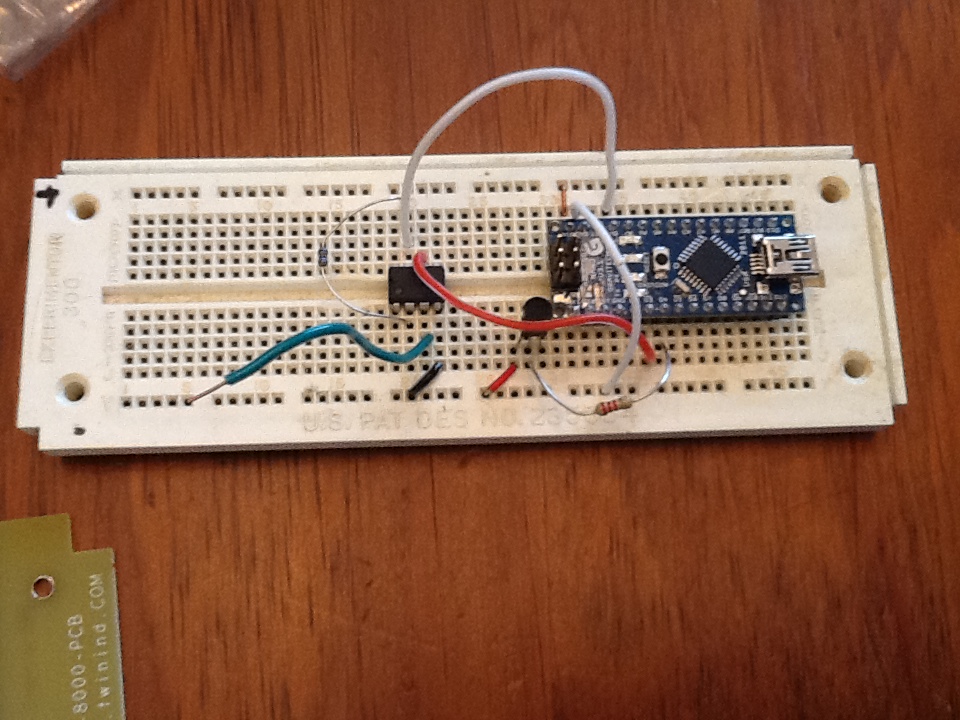

I ordered a Arduino Nano and put together a breadboard of what I though would work for hardware I wrote a couple simple sketches (that's what they call an Arduino program) to test the input from the tach and the output for the oil pressure. The advantage of being software based I could test each separably before I tried to get the logic between them working. This is my breadboard configuration.

From the breadboard I soldered the parts on a circuit card and mounted it in little box with a D-Sub connector. I wanted to box to be easily to remove for programming when needed.

The sketch I wrote uses a hardware interrupt the built in timer and one output pin. The Arduino has way more capability and lots more input and output pins but they were not needed. I'm sure a real software engineer could do much more efficient code but it works.

For now I'm driving gas free, I will try to get another post up soon with some energy usage.